Testing a NAVAC DI Pump on the Fly

While measuring vacuum for the purposes of determining the ultimate system pull down and decay should be done as far from the pump as possible, there are several very useful reasons to utilize the onboard vacuum gauge on the NAVAC DI series pumps.

While measuring vacuum for the purposes of determining the ultimate system pull down and decay should be done as far from the pump as possible, there are several very useful reasons to utilize the onboard vacuum gauge on the NAVAC DI series pumps.

Rig Restriction & Leakage

Checking the reading on the pump gauge against the vacuum can give you a quick look into how potentially leaky or restrictive your connection rig may be. While the vacuum level at the pump will always be lower at the pump than at the system, the greater the differential between the pump and the system, the more likely the vacuum hoses are leaking, restrictive, or off-gassing.

Pump Pre-Testing

Before starting any evacuation job, test the ultimate pull down of the pump with nothing connected by simply closing off all the ports and checking the readout. NAVAC pumps also provide an ultimate pulldown specification for the pump, so you have an ideal target to work towards. If the pump fails to pull down too close to the ultimate target after 1 minute, then change the oil and try again.

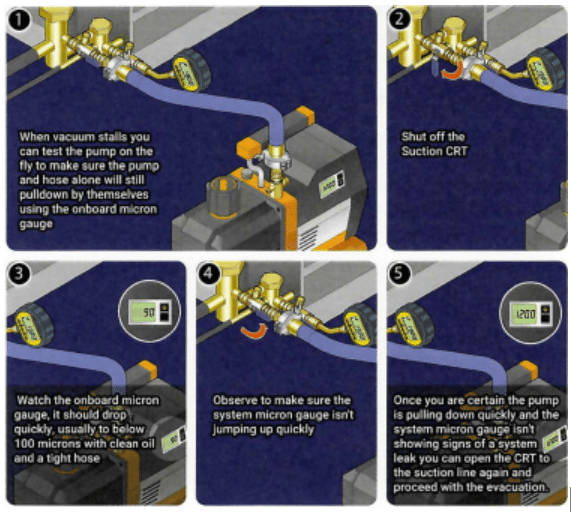

On the Fly Pump & Oil Testing

Sometimes when a vacuum stalls, you may suspect that the pump or pump oil is causing the issue. When this happens, you can simply shut off the CRT(s) at the system, and see how quickly the pump pulls down on itself and the connecting hoses. If the pump is no longer performing as expected, you can change oil and try again without losing the system vacuum or moving the system vacuum gauge.

Vacuum Gauge Reference

On occasion, you may suspect your system vacuum gauge isn’t working properly. While checking it against another gauge isn’t a perfect comparison, it’s convenient to have another gauge handly to check against. An onboard gauge makes it easy as connecting the vacuum gauge to the ¼’ port on the pump with the others capped and comparing the readouts.

This article was originally printed in Review of Vacuum for Service Engineers