Why It’s Important for HVAC Pros to Not Overlook Oil Integrity

HVAC contractors frequently overlook a particular element of evacuation – oil integrity. Oil integrity and moisture management need to be a key focus point. Here’s why: you could have the most expensive pump in the world and the most elaborate and high-end vacuum rig in-between that pump and the equipment, yet if you have wet oil, you will go nowhere.

To be successful, it is important to be able to fluently speak about and demonstrate how to manage moisture. An HVAC technician needs to be able to performance test the pump itself before, during, and after an evacuation.

If there is a presence of moisture in the crankcase, the two-staged vacuum pumps used in the HVAC industry will be completely incapable of achieving the deep level of vacuum that they are built for.

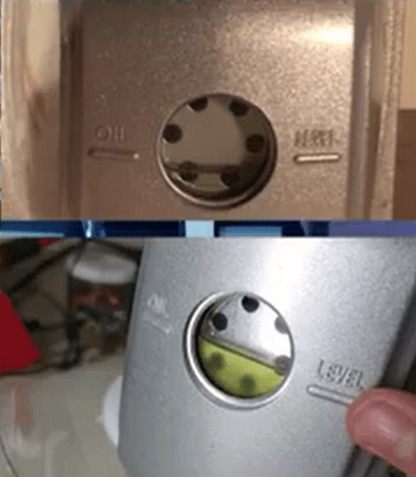

Traditionally, the rule of thumb for technicians was to analyze how the oil looked. They would glance at it before a job and if it looked yellow or milky, it was probably time for an oil change. And it’s certainly true that if your oil looks like that, you have moisture in the oil and it should be changed. The issue is that the performance ability of that oil was degraded long before the color change was visible. Therefore it’s important for us to identify a way to determine oil integrity preemptively, allowing us to catch the problem before it becomes a problem, avoiding unnecessary delay in our vacuum evacuation process.

How to Performance Test Your HVAC Pump

Remember, the pump is incapable of achieving its rating if the oil is not dry. Therein lies the answer: to performance test our pump and remove all doubt that it’s ready to go, a vacuum must be pulled on the pump itself, and it must be able to pull the one it is rated to. It sounds easy enough, you need a micron gauge, you need a pump, but what is the “x factor”? It’s the number the pump is rated for.

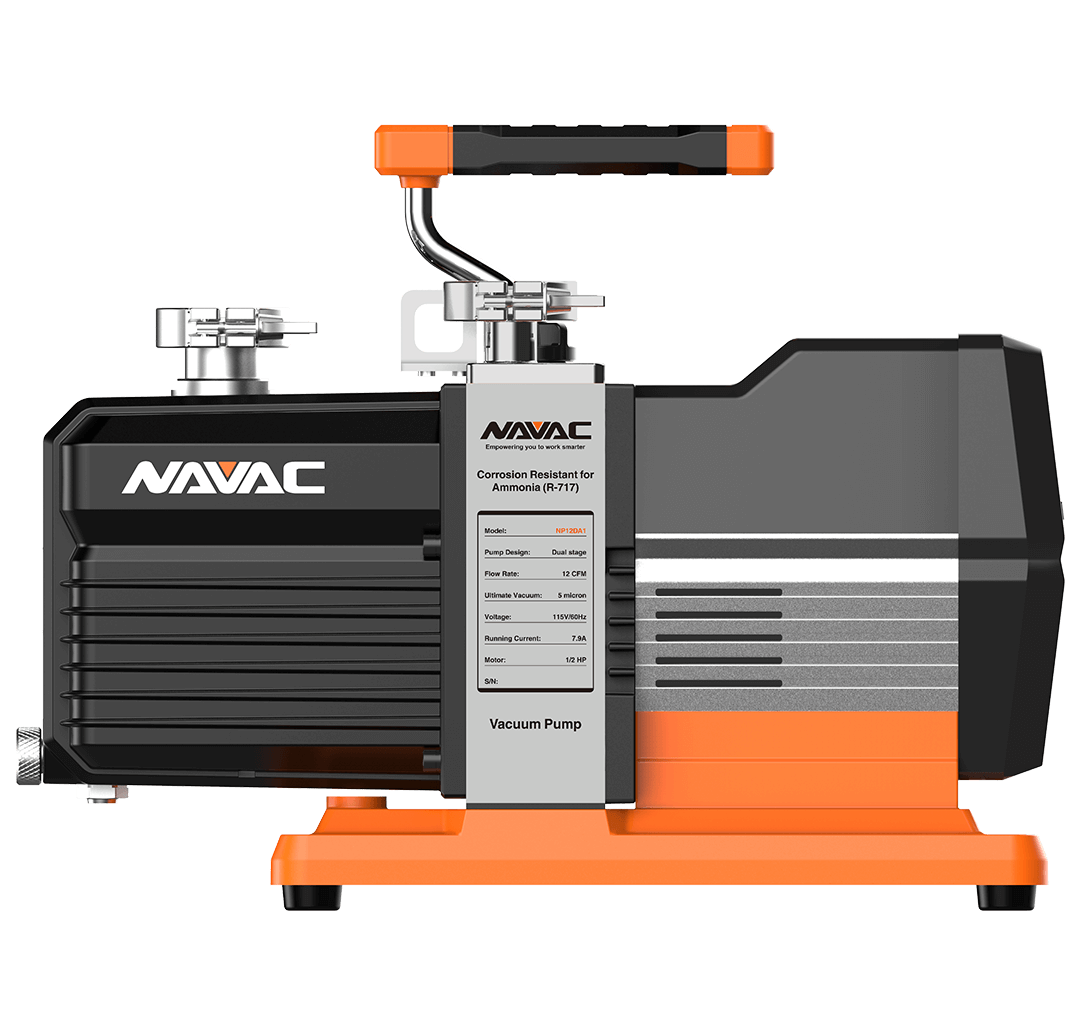

This is a problem that NAVAC has a solution for, right on the nameplate, where you can read the ultimate vacuum in microns.

By hooking up a micron gauge to the quarter inch port of you vacuum pump, turning the pump on and observing the reading, you will be left with one of three outcomes:

- You’ve got great, clean, dry oil in that vacuum; indicated when after turning the pump on, within seconds, it will pull down very close to, achieve, or exceed that reading listed on that name plate. In this case, you are ready to go!

- You turn the pump on and see that micron gauge go down, but before coming anywhere close to what its rated value is, it stalls and stops without any further progress. This is a textbook indicator that there is a presence of moisture. Remember, the vacuum pump is incapable of achieving a deep vacuum with the presence of moisture in that oil. This test took seconds to do, and left no room for speculation: you must change the oil.

- You turn the pump on and nothing happens. If you know you have a good micron gauge, your motor is running on your pump, but nothing is happening, that is a quick indicator that you have had a mechanical failure.

The convenience of a process like this is even more exaggerated with our DI series, our flagship pump the 6 and 8 DI; these have a micron gauge onboard, which makes the process even more streamlined, as you don’t have to hook up micron gauge. The test is simply done by turning the pump on, with the caps on the vacuum tree, and within seconds you will have your answer.

As you can see, checking for oil integrity is a simple process, yet one that should not be overlooked when it comes to the performance of your vacuum.